The Double Threaded Insulator

by Eric Halpin

Reprinted from "Crown Jewels of the Wire", July 1991, page 19

The development of threaded pinhole insulators is a history of both man's

technological tribulations and ingenuity. In the same manner that the actual

electromagnetic telegraph and its operating apparatus was continually upgraded

and refined, so was the parallel development of an essential component: The

perfect insulated wire securing device.

The earliest form of insulators (1844)

were comprised of glass plates surround a shellac-laden cloth holding a wire

within a notched crossarm. By 1845 a glass insulator similar in shape to a

bureau knob was used with unsatisfactory results. In 1846 a center notched glass

block was being used in a rapidly expanding telegraph industry. The next

major development was the concept of suspending the wire using an insulated iron

hook. By 1850 industry requirements for a more successful insulator resulted in

continual new styles and wire securing concepts, most notably was an insulator

with a smooth cylindrical and tapered pin hole which was then jammed onto a

compatible wooden peg. The earliest of this design is referred to as an

"egg" insulator, and there were many other threadless styles soon to

follow.

But without question, the greatest developmental concept for

a insulator was in 1865 when an internal screw thread was patented by Louis

Cauvet. Since 1870, mass production of threaded pinhole insulators began and the

industry never looked back. Despite the probable costs of insulator

manufacturing companies buying in for the rights to use this patented threading

concept, they had little choice as it was obvious to all that it was the only

proper road to follow.

|

|

|

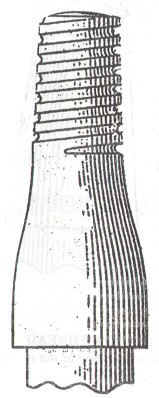

Drawing #1. THE STANDARD ACME THREAD

One continuous thread starting at pin

top, and sloping at a 10 degree angle. |

In Canada, one of the earliest threaded styles is a telegraph insulator known

in the hobby as the CD 143. Of the many sub-varieties in this style, there is an

insulator that is truly unique within the world of insulators, the double-threaded insulator.

In North America, the standard for general utility

or "acme" threads such as those found on insulators, is four threads

to the inch. This thread is formed by one continuous ridge starting at the top

of the mandrel and pinhole crown and winding down towards the base at a 10

degree helix angle (Drawing 1.) The "acme" thread is sometimes called

a "knuckle" thread. Some of the earliest forms of "acme"

threads were actually made in a "V" or sawtooth -- shape up until 1880

or so. The machined mandrel with the threads and the resultant pinhole is always

tapered so that the threads fit into each other by compression or interference.

A true cylindrical mandrel and pinhole would result in no compression contact

until the pin reached the top of the insulator and this could lead to a crown

stress fracture.

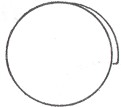

The doubled threaded insulator also has four threads to the

inch but instead of one continuous ridge it has two. This is called a multiple

start thread. The double ridge is achieved by starting each ridge 180 degrees

opposite each other and winding each ridge down the mandrel and thus the

pinhole. Because both ridges must fit within the same given area, the

"angle of the helix" must be double that of the standard helix or 20

degrees (Drawing #2). When a double threaded insulator is screwed into a

standard pin, it will still hold tight but will cross thread on the first

turn.

It is not known why or who came up with the idea of double

threading insulators but there are some advantages as follows. First and

foremost is that the lineman can screw the insulator onto the pin twice as

quickly since with each revolution the insulator moves down twice as far on the

pin. The second advantage is since there is twice the thread surface, if follows

that there is greater compression or interference contact with each thread and

thus increasing the holding power.

|

|

|

Drawing #2. THE DOUBLE THREAD

Two continuous threads starting at pin top and

sloping at a 20 degree angle. |

If the double threaded ideas was so good, why didn't it catch on within the

industry? I suspect that the double thread may have been an attempt to

circumvent the original Cauvet patent to eliminate any remuneration costs. If

the double thread was challenged as a patent infringement it would likely have

succeeded. It is also very likely that the North American telegraph industry

recognized the need for standard of construction, maintenance and operation.

Regardless of how or why this double threaded insulator came into being,

there can be no doubt about how unique this insulator pinhole is!

So far, I have identified that there were three different molds used to

manufacture this scarce and highly desirable variety of CD 143. The differences

are very slight and observable only after extremely detailed examination. All

are two piece molds (MLOD), have "V" threads and were subject to a

wide level of glass pour resulting in height differences of up to 3/4", but

of further great interest to collectors is the spectacular colors that can be

found in the double threaded variety as follows:

Aquas: pale to dark and tones of blue and green

Greens: light to medium and tones of olive and yellow

Blues: light to medium and tones of steel, cornflower and gray

Yellow: light to medium and tones of green and amber

The existence of this unique family of double threaded insulators would

likely have not become known if it wasn't for the very keen and observant eye of

Grant Salzman. Mr. Salzman gave to the world of insulator collectors the

knowledge of this insulator in a November, 1981 Crown Jewels of the Wire

article entitled "Me and the 143".

|